What is Pellet Mill Plant?

Pellet mill plant is composed of several sections of devices, which is the union of continuous or semi-continuous production line. It can be also called pellet mill plant or wood pellet line, for the complete pellet plant is always used to produce wood pellets.

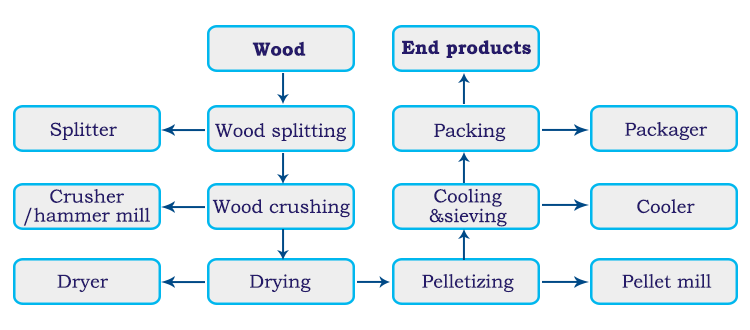

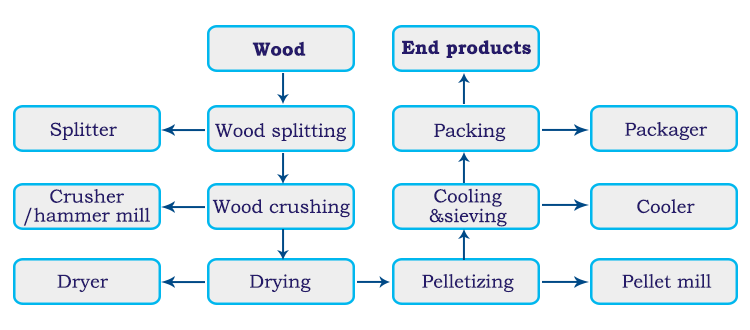

Pellet mill plant includes the sections like grinding, drying, pelletizing, cooling and packing, etc and the conveying equipment connecting each section.

According to the different required production, the types of pellet plant are different. It is not necessary to put all the above equipments and steps into use. ABC machinery will arrange the best process and machine for you as per the processing of materials and the location of factory. Of course the pellet mill is an indispensable device during the processing procedure.

Pellet Plant Flow Chart for Wood

From the aspect of pellets yield, pellet mill plant can be divided into small pellet plant(under 500kg/h), large-scale complete pellet plant(more than 500/h) and small-scale pellet production line (mobile type). Pellet mill plant with different yields uses different pellet mills. Flat die pellet mill is usually used in small-scale production line while ring die pellet mill is primarily suitable for large-scale production line.

500-600KG/H Small Pellet Plant( for Chile client)

6T/H Large Pellet Plant(Malaysia Project)

The Key Pellet Mill Plant Equipment

Features and Advantages of Complete Pellet Plant

-

It is used in pellet production line.

-

It adopts special materials that prolongs the life span of pellet plant.

-

It is easy to operate.

-

It saves labor costs.

-

It can produce pellets continuously.

-

It can be customized according to clients’ requirements.

-

It is capable to process multiple kinds of biomass raw materials.

-

The end products, fuel pellets, improve the combustible feature of raw materials.

-

This design consumes lower energy and make sure the stable running of the complete pellet plant.

-

Complete pellet line improves the degree of automation.

-

The processing materials are mainly agricultural and forestry wastes and wood processing wastes. The mainstream of materials are sawdust, wood waste and other biomass materials.

Why Choose ABC-Machinery Pellet Plant?

ABC Machinery has already been in pellet industry for more than ten years, so we have rich experience on designing, constructing, and installing large and small scale production lines. And we are engaged in R&D production. The equipments produced by our company are sold to many countries and get great feedback. Besides, the price of our machine is reasonable, the quality is guaranteed, and the service is superior. We design the products that are more suitable for the requirement of clients. So don’t hesitate to contact us.

ring die pellet plant

ring die pellet plant

flat die pellet plant

flat die pellet plant