Small Hammer Mill

This kind of small hammer mill is used in small pellet production line for its small volume. Small hammer mill can process corn, corn straw, peanut shell, bean straw, branches etc, materials with less than 14% moisture content.

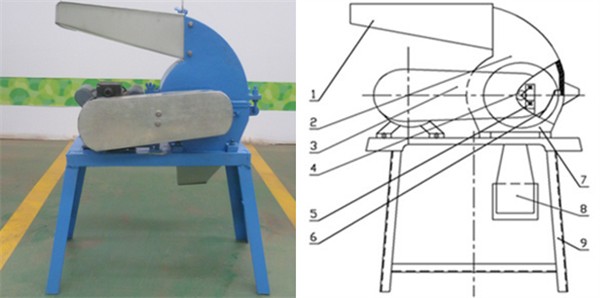

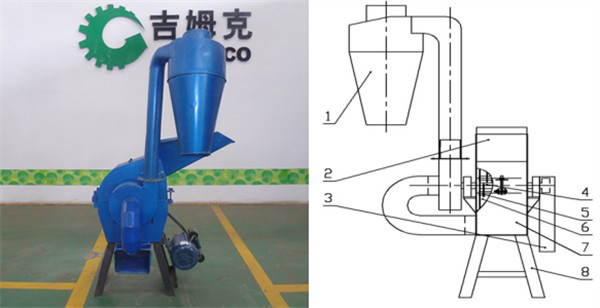

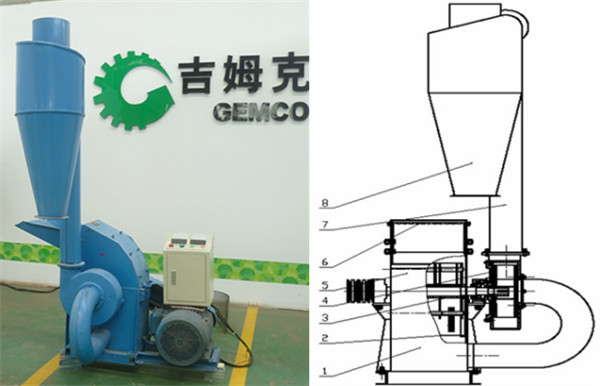

Structure of Small Hammer Mill Grinder

1. Feeding hopper, 2. Upper body, 3. Protective shell, 4. Rotor, 5. Blade, 6. Siever, 7.Lower body, 8. Discharging outlet, 9. Foundation frame.

1. Cyclone, 2. Upper body, 3. Protective shell, 4. Rotor, 5. Blade, 6. Siever, 7.Lower body, 8. Foundation frame.

1. Lower body 2. Siever 3. Rotor 4. Air fan 5. Upper body 6. Feeding port 7. Discharging outlet 8. Cyclone

Working Principle of Small Hammer Mill

After the materials go into the chamber of the hammer mill, they will be crushed by the high-speed of rotary hammers. Under the function of centrifugal force, the crushed materials are along the outer edge of the rotor and smashed by the squeezing, crashing, striking of the hammer, toothed plate and screen. The smashed materials are sent out of the hammer mill under the function of rotor and draught fan. The particles that don’t pass through the screen hole will be left in the hammer mill repeating the above steps until they are sent out of the hammer mill.

Advantages of Small Hammer Mill

- Superior design, high-quality finished products;

- High efficiency, low energy consumption;

- Suitable for grinding wood materials and agricultural wastes such as logs and crop stalks;

- Easy to operate and maintain;