Buy Electric Pellet Maker for Home Use

Introduction of Electric Pellet Maker

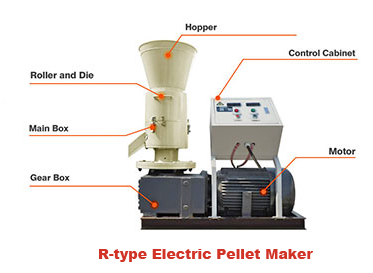

Electric pellet maker, is a kind of flat die pellet press with electric motor, is also called electric pellet press. It is mainly composed of die, roller, main shaft, electric control cabinet, locking ring, hopper, blade, adjusting bolt. When the pellet maker is connected to the power, the electric motor drives the main shaft rotating, and there begins the friction between the roller and the die. Under the large pressure between them, the material will be pressed into the other side of the die through the die holes. Then the blade will cut the formed pellets into uniform length, and you can get the perfect pellets.

D-type and R-type Electric Pellet Maker

- D-type electric pellet machine is based on the rotating die, which the roller is stationed, while the flat die is driven to rotating by the main shaft. The raw materials are always be the agro biomass waste or the soft wood, such as, the rice husk, bamboo powder, sunflower husk etc. The production capacity is in a range of 50 kg -400 kg/h, according to different powers in 5.5kw to 22kw, powered in three phase electricity. For the appearance, both of normal one and fully covered electric motor are equipped. Besides, D-type pellet maker is a classic version, which is the optimal choice for the people who begins to use the pellet maker.

- Differ from the D-type, the R-type electric pellet mill is base on the rotating roller. On the contrary, it means that the roller is driven by the main shaft and the die is fixed, which his the pro version of D-type. And it can press hard wood like elm tree, oak, birch, cypress, maple etc. The capacity ranges from 80kg/h to 800kg/h on the power of 7.5kw to 55kw, so, it is also suitable for scale pellet production in pellet factory(How to set up a pellet factory>>). Those who have higher requirements and flexible budget can list it on the sheet.

More Details about Electric Pellet Maker

- The diameter of the flat die hole is in range of 4mm -12mm.

- All of our electric motors are certificated by CE, making sure the stability of the power supply.

- All the spare parts adopts high quality raw materials, and the main components flat die and roller, are made by the alloy steel, the hardness is 40HC-60HC.

- The life span of the roller and flat die is not less 800 hours. And the service life of main parts respectively are: one year for the electric motor and gear box, five years for the upper body.

- The electric pellet making machine is removable, you can move it to anywhere only there is electricity.

- When you use the electric pellet mill for the first time, you had better do the testing job for your raw material.

Welcome to contact us for more information about our electric pellet maker.