Making Best Charcoal Briquettes with Wood Charcoal Making Machine

What is Wood Charcoal Briquette?

When talking about the wood charcoal, the initial charcoal is made from the burning wood with separating with the air, using the certain of temperature to carbonizing the wood, then becoming the charcoal briquette that we need. We call it original charcoal due to its direct production from the wood. This kind of wood charcoal generally has high price because of the high cost.

(original charcoal and mechanical charcoal)

Wood Charcoal Manufacturing Process

-

Step 1 Raw Material Preparation

-

Step 2 Raw Material Process

Wood Cutting Machine or Wood Splitter

Wood cutting machine is mainly used for cutting of wood log, branches, undersized log, residue wood material and shrub.

| Type | Crushing range (mm) | Output (t/h) | Inlet size (mm) | Overall weight (t) |

Overall dimension (length*width*height) |

| HX1000 | ≤350 | 2-3 | 440*380 | 2.8 | 3800*1600*2700 |

TFS Series Crusher

This series crusher is designed to crush the raw material with size less than 10mm, the length of all materials can not larger than 200mm. And the different raw materials require different crusher type.| Type | Branches | Corn stalk | Peanut hell | Bean stalk | Corn |

| TFS198 | 20~150 | 20~150 | 180-350 | 20~150 | 240~400 |

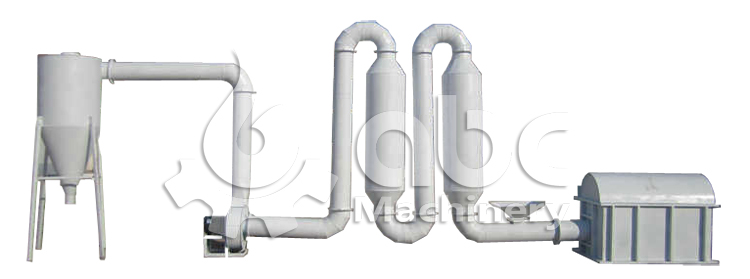

Dryer

Air flow dryer is designed with hot air pulse, also called as hot air duct dryer, is featured with the advantages of direct heating, fast drying, foldable installation, save space.| Type |

Output (kg/h) |

Power (kw) |

Inlet size (mm) |

Overall weight (kg) |

Overall dimension(mm) (length*width*height) |

| GC- DL -7.5 | 400-500KG | 7.5 | < 3 & < 5 | 2100 | 1300×200×3300 |

-

Step 3 Wood Charcoal Briquettes

Mechanical charcoal: The raw material enters the wood charcoal making machine to make briquette. The wood charcoal making machine processes the raw material into briquettes with uniform size and density, and then the briquette enters the carbonization furnace or carbon kiln for carbonization. During this process, the necessary machinery are wood charcoal making machine, carbonization furnace or carbon kiln.

Wood Charcoal Making Machine

The wood charcoal making machine is the main molding equipment for wood charcoal briquette production. It can press the granulated raw material (length≤5mm, diameter≤3mm) with the moisture less than 12% like bamboo dust, wood, fruit shell and stalks into solid salary stick with center hole without adding any bonder.| Type | Output | Power | Briquette diameter | Net weight | Volume |

| GCBA-II | 280~350 | 22+5 | Φ=40mm, 50mm, 60mm, 70mm | 780kg | 1500*1200*1600 |

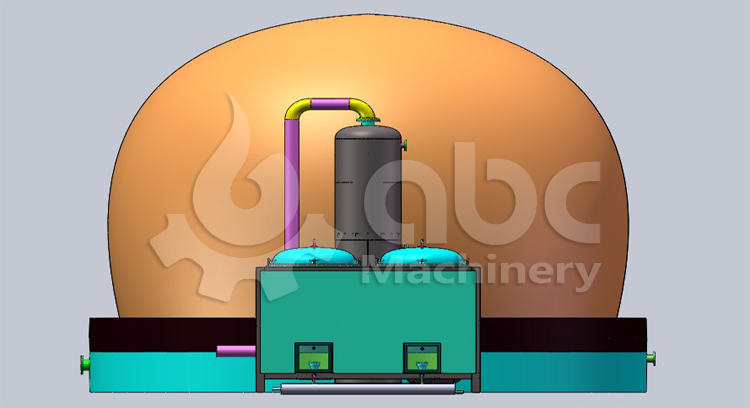

Carbonization Furnace

There are two types of carbonization furnaces including wood carbonization equipment, used for carbonizing branches, wood block, coconut shell briquette, mechanical wood briquette etc. This type carbonization furnace can be equipped with gasifier device to collect the gas for changing into flammable gas used for carbonization furnace or other applications.The other one is the powdered carbon production line used producing rice husk, sawdust and bamboo dust into carbon powder then be produced into active carbon.

Dry Distillation Carbonization furnace

Wood charcoal production is a holistic process. Different raw materials and different requirements for finished charcoal will also lead to different production processes. ABC Machinery provides you with free professional consultation to design the most reasonable production process for you.