Best Briquette Processing Machine for Sale to Manage Agricultural Residues

Best Management of Agricultural Residues

Agricultural residue is the non-product output of agricultural production and processing, which is widely seen here and there. Such as, coconut shell, cotton stalk, sunflower straw, rice husk, corn cob, bean stalk, palm fiber, bagasse, chestnut shell etc. Among these residues, there are some valuable stuff for our daily life.

Recent years, several methods are measured in agricultural residue management. For example, making straws into animal feed or fertilizer. However, more residues are not suitable for being made into animal feed or fertilizer like corn cob, palm fiber etc. For these kind of agro residues, making them into briquette used as fuel by briquette processing machine for sale is the ideal management. The finished product, belonging to green energy, is easy to burn and no bad gas produced during the combustion, meeting

Featured Briquette Processing Machine for Sale

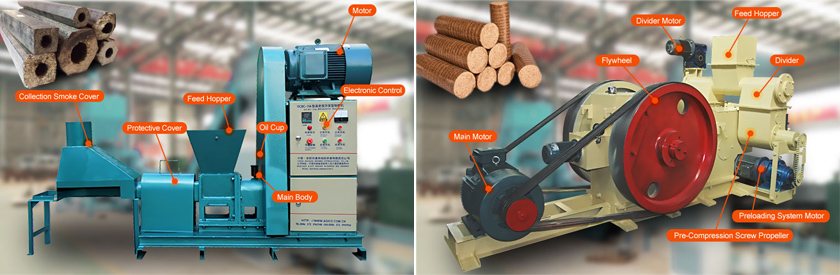

The equipment for making agro residues into briquette fuel is called briquette processing machine for sale. According to mechanism working principles, it make the agro residues into high density briquettes with the shape of blocks or robs. It has been developed into two types including screw briquette pressing machine and punching briquetting equipment, which are widely spread around the market.

The screw briquette processing machine is also called charcoal briquetting equipment, adopting the screw to push the raw materials into the forming sleeve. Under the high pressure from the screw, the loose raw material is formed into high density briquette. The finished briquette is with the shape of a hollow center and carbonized surface, but this is not the real charcoal, which is needed to be carbonized in the carbonization furnace.

Different from the screw type, the punching type briquetting press equipment adopts the working principle of mechanical stamping, giving the raw material great pressure to make them into high density briquettes with the shape of cylinder. With replacing the different size forming sleeve, the punching briquette processing machine can produce both of pellet in the diameter of 8mmto 10mm and briquette in the diameter of 22mm to 85mm.

Strength of Briquette Processing Machine for Sale

- Flawless product raw materials range. With the briquette processing machine, not only the agricultural residues but also the wood wastes like wood chips and shavings, wood branches, leaves, sawdust etc can be produced into useful fuels.

- Huge finished product application. The finished briquette has various size, easy to be used in many occasions, such as, home heating and cooking, enterprise heating, public heating, power generation station and other places where needs fuels.

- Low cost but huge return. The raw materials for making briquette is seen easily everywhere, easy to be collected, costs less investment; The briquette produced by briquetting equipment has high density and uniform shape and size, easy to store, pack and transport, saving managing cost. And the briquette has high combustion value, efficiently relieve the tension situation of less and less traditional fuel.

- Easy payment options. With the briquetting press machine for sale, you not only have a green fuel producer, but also possess one chance to increase your income. You can increase your income by selling the briquette you produce or the briquette processing machines.

If you have any idea with our briquetting equipment, welcome to contact us for more information.