Biomass Briquette Machine Make Wood| Peanut Shells |Sawdust Briquettes

Why use Biomass Briquette Machine

Human has used energy for a long history with coal taking an important part in energy using. While as the industrial develops, the disadvantages of coal burning has been revealed, the burning gas polluted the environment seriously, resulting human living environment went bad. Also, due to the non-renewal and very long time of coal forming, quantity of coal has been less and less. In this case, people started to looking for new energy resource for replacing the fossil fuel to protect the air and save energy cost.

Raw Material for Biomass Briquette Machine

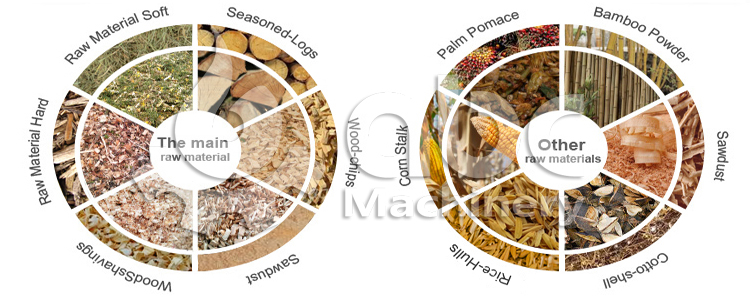

Biomass briquetting technology comes in view and develops based on the development of biomass energy, and biomass fuel is renewable and clean for its inexhaustible and green raw material. Variety of raw materials can be used for making biomass briquettes.

Another one is process waste. All the processing will leave waste, including wood and crop processing, such as, wood chips, bamboo chips, shavings, sawdust, peanut shell, rice shell, coconut shell, coffee shell, bagasse, corn rod, twigs, branches, barks etc. the only question is the moisture content, the biomass briquette machine requires the moisture content of material should be around 12-15%, and when collecting material, you can not test every piece of material. That needs you equip the relative machine to meet the requirement.

Salient Features of Biomass Briquette Machine

- Biomass briquette machine can make wide ranges of raw materials in to briquette fuel, including agro waste like rice husk, peanut shell, cotton vine, corn straw etc. and processing waste like wood chips, shavings, sawdust, branches, barks etc.

- After briquetting, the raw material is turned into high density briquette with high combustion efficiency, low dust, high heating, no harmful gas produced, is the best substitute to fossil fuels.

- The briquette machine can produce briquette with different diameters ranging from 8mm to 80mm, what you need only to do is replacing the mould, and the length of briquette can be decided by your requirement.

- The finished biomass briquette can be used for home cooking and heating, household fireplace, public heating, industrial boiler, BBQ fuel, even the biomass electricity generation.

Biomass Briquette Making Processing

Before you ready to make biomass briquette, you need to decide what capacity you want to make, and check the moisture content and size of your raw material is proper or not. The single biomass briquette machine can produce 0.5t -5t of biomass briquette. If you have no more requirement for output capacity, and the material is proper, you can turn on the biomass briquette making machine to make briquette.

If you have interest in our biomass briquette machine, you can contact us for more information.