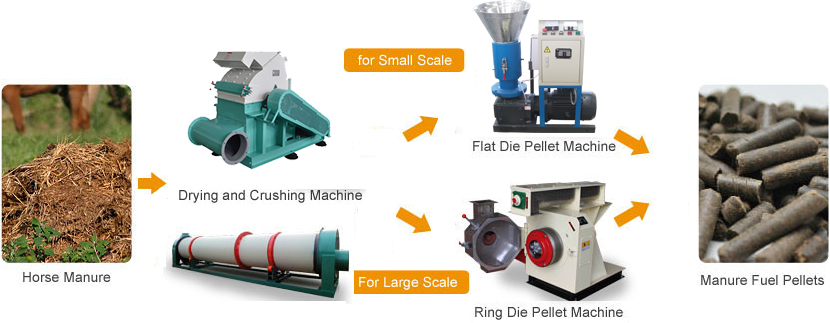

Horse Barn Waste Pellet Mill Turn Waste into Value

What is horse barn waste?

Fuel pellets can be obtained by compressing any one of many different raw materials. We are often asked questions about the use of raw materials for producing fuel pellets. It is true that most waste materials can be used for this purpose, but only some of them result in a good fuel. Horse manure and horse bedding waste are among those. Since it is often costly to properly dispose of these types of manure, the producer chooses to compress them into fuel pellets often using a horse barn waste pellet mill is actually killing two birds with a single stone.

Whether the horse barn waste pellets have urine smell?

Actually, there is no urine smell when burning the pellets made from horse manure or horse bedding wastes. This is because the manure or wastes are dried before pelletizing. The smell is gone. Besides, the heat during the pelletizing process encapsulates the pellet. With the right preprocessing and quality horse barn waste pellet mill, you can made premium fuel pellets from horse manure and horse barn wastes, which smells like common wood pellets when burning.

The advantages of horse barn waste pellet mill.

First of all, horse barn waste pellets made by horse barn waste pellet mill are convenient, easy to store and they are made from renewable sources. More important horse manure and barn wastes have proved to be a source of high-quality fuel pellets.What’s more, naturally, this eco-friendly method of pellet production is especially suitable for various farm owners that have the access to this particular materials. They also can use it as a practical and cheap alternative to other fuels, but this approach also offers other benefits. For instance, it can considerably reduce the potential waste disposal costs. Of course, other byproducts such as chicken manure and bedding can also made into pellets by horse barn waste pellet mill.

Last but not least, horse barn waste pellets are as good as fuel oils. To boot, these pellets produce lower fuel emission and residues. People start living organically not only to save the environment but to combat health risks brought about by using artificial products.