How to Choose Pellet Press Machine

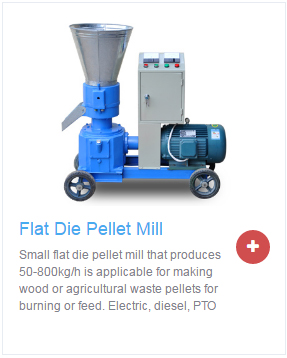

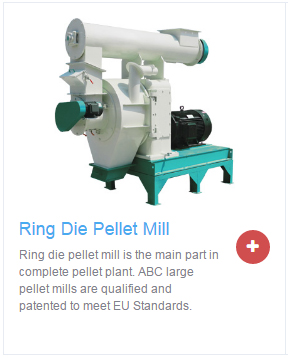

Pellet press machine is generally divided into two types, one is flat die pellet press machine and another is ring die pellet press machine. The former is suitable for small scale pellet production line while the the latter is suitable for large scale pellet production line. Both of flat die pellet machine and ring die pellet machine can realize in parallel production by multiple pellet presss. When you build your own pellet production line, you should consider many factors, like raw materials, place, power, labor and so on, then you should choose the proper pellet machine for your pellet production.

Mainstream flat die pellet press machine and ring die pellet press machine style.

But how do we choose a pellet press machine?

We should take consideration of the following factors:1. The appearance. The spray paint of the pellet machine surface and stainless steel/plating layer parts should be uniform, smooth and firm. A good looking pellet press surface reflects the pellet press equipment manufacturer’s extent of specialization.

2. The machine body and frame. You should check whether the pellet machine body and the frame are firm. Because they are the foundation of the whole pellet machine. The lock nut and the fastening bolt of the pellet press should be tightened.

3. The ring die rotating situations. You should check whether the ring die will skip or rub other parts. For the above reason, it will decrease the yield and damage the ring die and other parts decreasing the pellet press service life span.

4. The warehouse door. During the ring die pellet press machine production, you should check whether the warehouse door is designed in the right and suitable place and whether the door is opened and closed easily and whether the door leaks materials.

5. Test running. You can have a free test running of the pellet machine. Before the test running, you should check the lubricating condition of the gear box and the lubrication points. The first running doesn’t need to be too long, and the rotating direction of the spindle motor should be the same with the marked direction. If they are different, you should stop the machine and plug in phase commutation. After every thing is normal that is no irregular vibration, crash of gear, etc, you can feed materials.

6. The pellet considerations. Pellets quality is the direct standard of the pellet press machine quality. The pellets should be uniform, smooth, bright on the surface without cracks and the breakage rate of the pellet shouldn’t be more than 5%.

7. Pellet press manufacturers. A good pellet press machine manufacturer is a key factor for the pellet machine purchaser to buy a high-quality pellet machine. It is like ABC Machinery, who will supply superior machines to the clients, and that will get rid of a lot of troubles for the pellet press machine purchasers and give them the best service and after sale service.

The above factors are not all the factors to choose a pellet press machine, but they can help you to choose a better pellet press. You will get a largest benefit after you choose a perfect pellet machine according to the above factors.