How to make pellets for a pellet stove?

Wood Pellet for Stove

As one new kind of green energy source, wood pellet has been come into the view of public for a long period, an increasing number of people choose to use wood pellet as their daily fuel, even there are people start to produce wood pellet by themselves, which leads pellet making machine becoming increasingly popular as well.

About Pellet Making Machine

Pellet making machine is specially designed and manufactured for making fuel pellets. Generally, it is divided into two big types, including flat die pellet machine and ring die pellet machine.- Flat die pellet machine is also called as small pellet press due to its small size and simple structure, adopting flat pelleting die inside the machine, widely used for making wood pellet at home, in backyards and small pellet production line.

- Ring die pellet machine adopts the die just like a ‘ring’. Ring die pellet machine has a large production capacity, thus widely used for scale fuel factory, large pellet production line and industrial stove.

How to Make Pellets for a Pellet Stove?

- Making Pellets with Small Pellet Press

(Eclectic-motor type, diesel-engine type, PTO type, gasoline-engine type)

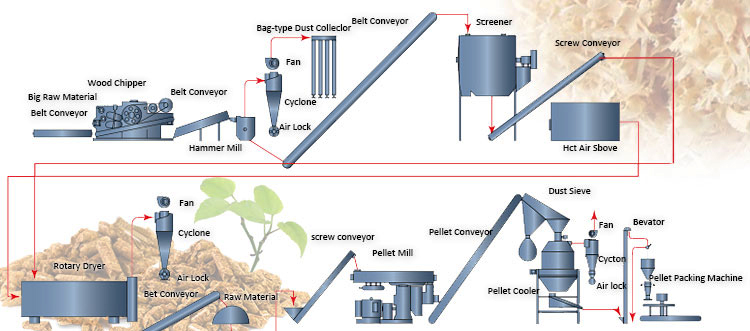

- Typical Pelleting Process in Pellet Making Plant

Chipping processing is mainly set for processing the wood log or the raw material with big block, thus this processing is optional, if your raw material is not in big size, you can start from the next processing.

2. Crushing processing

Due to the strict requirements for size in pellet production, the raw materials should be crushed into the proper size less than 3mm. Hammer mill can help to process the raw materials into the proper size.

3. Drying processing

Raw material moisture content affects the final pellet quality greatly. Too dry raw material is not easy to formed in pelleting processing, and too wet raw material is easy to glue with the inner wall of the machine. This processing is to adjust the raw material moisture content in a proper level.

4. Pelleting processing

In this processing, you can choose any type of pellet press which is decided by the production output requirement. Small pellet press production is 50kg/h to 600kg/h, and ring die pellet machine is in 500kg/h to 2t/h. And if you have higher requirement for output, you can set two or two more pellet machines in this processing.

5. Cooling and sieving processing

The fresh finished pellet has high temperature, thus needing to be cooled for later packing. Sieve is installed near the discharging hole of the cooling machine to separate the dust or the breaking pellets from the well formed pellets.

6. Packing processing

After the sieving processing, packing machine is equipped to weigh and pack the pellets into bags. Half auto packing machine or auto packing machine is equipped in this processing, and at the end of this processing, the bag-sewing machine can seal the pocket of the bags for later transportation or selling.

Making pellets for a pellet stove can be challenging, the lack of a one-size-fits-all process means that it can be more art than science. More detailed information about making pellets for a pellet stove can be offered by contacting us.