Making Biomass Briquettes by Using a Briquetting Machinery

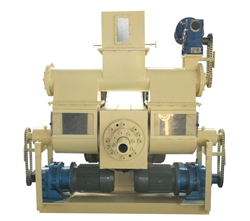

Briquetting machinery is used to produce briquettes. There are three kinds of briquetting machinery in the market, punching briquetting machine, screw briquetting machine and hydraulic briquetting machine. ABC Machinery mainly operates the first two kinds of machinery, punching briquette machinery and screw briquette machinery. We will give you the specific introduction in the following content.Punching Briquetting Machinery:

Brief introductionPunching briquetting machine is a good selling product in our company. It uses the high temperature and high pressure to make fuel briquettes, according to the different sizes of the molds, the briquettes can be made into different shapes, which is suitable for different applications. The density of the briquettes can be 1000-1300kg/m3, what’s more, each part is added lubricating oil by the forced lubrication system, which can guarantee the continuous running.

Model

Capacity

Density

Power of main engine

Weight

Installation space

Briquette Specification

Capacity

Density

Power of main engine

Weight

Installation space

Briquette Specification

Punching Briquetting Machinery

0.5-0.8 t/hr

1000-1300kg/m3

45KW

7000kg

About 80㎡

Dia.:8mm, 70mm

0.5-0.8 t/hr

1000-1300kg/m3

45KW

7000kg

About 80㎡

Dia.:8mm, 70mm

1. The punching briquette machinery can make full use of the waste raw materials.

2. It is energy-saving, and the energy consumption is less.

3. The end products from the punching briquetting machinery has high quality and high burning efficiency.

4. The punching briquette machine uses high strength of materials, especially for the quick-wear parts, so the punching briquette machinery is durable and the life span is long.

Screw Briquette Machinery:

Brief introductionScrew briquetting machine is also called charcoal briquette machine, and it is mainly used to make charcoal briquettes. Generally, there are two steps to make charcoal, the first step is to make briquettes, and the second step is to turn the briquettes into charcoal briquettes. The user needs to make a kiln to make charcoal. If you don’t know how to make the kiln, you can consult us, we will help you soul and heart.

The high-level charcoal briquettes can be used in the barbecue, and the barbecue food is delicious without any smoke.

Model

Output capacity

Motor Power

Electric heater

Heating Range

Size of briquettes

Size of inside hole

Density of briquettes

Weight

Overall dimension

Life of the inner former

Raw material moisture requirements

Output capacity

Motor Power

Electric heater

Heating Range

Size of briquettes

Size of inside hole

Density of briquettes

Weight

Overall dimension

Life of the inner former

Raw material moisture requirements

Screw Briquetting Machinery

300-350kg/h

18.5kw, 360v, 6 grades

2.2kw×2

280~350℃

Dia.60/50mm*L.500mm

Dia.16mm

1.3g/cm³

1000kg

2000*600*1700

1-2years

8~10%

300-350kg/h

18.5kw, 360v, 6 grades

2.2kw×2

280~350℃

Dia.60/50mm*L.500mm

Dia.16mm

1.3g/cm³

1000kg

2000*600*1700

1-2years

8~10%

1. The screw briquetting machine has simple structure, the it is easy for the operator to operate the machine.

2. The screw briquetting machinery can process many kinds of raw materials, that means the machine application range is wide.

3. The electric control system meets the CE standard, and the security level is high, which is save for the operator.

4. The screw briquetting machine pays more attention on the details. For example, we use the high-standard lubricating grease rather than the ordinary grease.

No matter which kind of machine, our company can make sure the briquetting machinery quality, the production efficiency and the low energy consumption. That is why so many users choose us.

The application purpose

Why should we use the briquetting machinery? Because the end products of the briquetting machinery is environmental, it can reduces the carbon elimination and improve our living condition. Besides, the raw materials are recyclable, and that relieve the energy crisis.

If you are interested in our product, please fill in the following chart and contact with us, we will reply on you at the top speed and introduce our product to you in detail.