Pellet Mill Die Decides Your Pellets Production

Pellet mill die is a key part in the pellet mill machine, and the quality of the pellet mill die has a huge effect on the pellets quality. So when we are choosing the pellet mill, we must pay attention to the pellet mill die quality.

Introduction to Pellet Mill Die

Pellet mill die is largely used in large pellet mill and small pellet mill. The pellet mill die can be divided into ring die and flat die. From the names of the pellet mill dies, we can know that they have different shapes, the former has a ring shape while the latter is flat. But both of the pellet mill dies have the same discharging principle. That is the materials are pressed into the die holes from one side, under the function of high temperature and high pressure, the materials come out from another side becoming pellets.

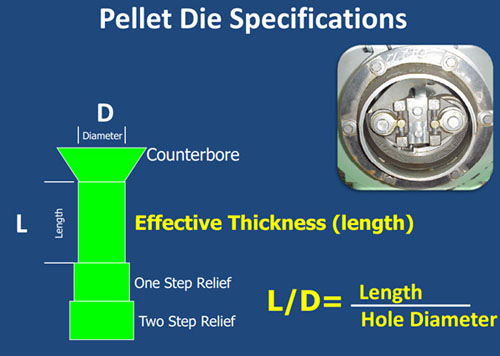

Both pellet mill dies have their own characteristics: flat die pellet mill die has a small volume and light weight, so it is easy to maintain and change. Ring die though is large and heavy, it is durable and has long service life time. The following picture gives the design specifications of the pellet mill die:

Specifications of Pellet Mill Die

From the picture, we can see that, the pellet mill die hole is designed into different parts: we will describe it from up to down. The top of the pellet mill die hole is a tapper which is easier for the materials to go into the die hole. The next part is the molding part which is the effective thickness of the pellet mill die, the pellets are formed in this section. The bottom of the pellet mill die is stepped hole which is used to keep the original compression ratio after the worn ring die is repaired.

Compression Ratio

The whole design of the pellet mill die hole should be according to the compression ratio that is L/D. The compression ratio of ring die should be matched with the raw materials. For example, the compression ratio of poplar is 1:6, the deal is 1:7, and wood shaving is 1:5.5, etc. From the figure, we can know that different materials have different compression ratios. The hardness of the materials decides the compression ratios. The higher the hardness of the raw material, the smaller the compression ratio will be. That means the loose materials are easy to be pressed into pellets for the loose materials have a lot of fibers which is easy to form pellets.

Compress Ration Test for Clients

So when you want to buy the ring die pellet mill, you should choose the right ring die compression ratio. While in ABC Machinery, you won’t worry that, for the ring die pellet mill is matched with several ring dies that have different compression ratios according to different materials. If your materials are the mixture of several different materials, and you don’t know the compression ratio, you can send the material mixture to us, we will help you to have a test and make the proper ring die and roller.

Some manufacturers produce the die with the same compression ratio, but told the users that the pellet mill can process any kind of raw materials. That is not right. If the die doesn’t have proper compression ratios, the pellets can not have an ideal form. ABC Machinery produces the die with different compression ratios according to the raw materials types guaranteeing the pellets quality.

ABC Machinery has single pellet mill die for sale, if you want to buy high quality of pellet mill die, you can contact us, and we won’t let you down!

Compression Ratio

The whole design of the pellet mill die hole should be according to the compression ratio that is L/D. The compression ratio of ring die should be matched with the raw materials. For example, the compression ratio of poplar is 1:6, the deal is 1:7, and wood shaving is 1:5.5, etc. From the figure, we can know that different materials have different compression ratios. The hardness of the materials decides the compression ratios. The higher the hardness of the raw material, the smaller the compression ratio will be. That means the loose materials are easy to be pressed into pellets for the loose materials have a lot of fibers which is easy to form pellets.

Compress Ration Test for Clients

So when you want to buy the ring die pellet mill, you should choose the right ring die compression ratio. While in ABC Machinery, you won’t worry that, for the ring die pellet mill is matched with several ring dies that have different compression ratios according to different materials. If your materials are the mixture of several different materials, and you don’t know the compression ratio, you can send the material mixture to us, we will help you to have a test and make the proper ring die and roller.

Some manufacturers produce the die with the same compression ratio, but told the users that the pellet mill can process any kind of raw materials. That is not right. If the die doesn’t have proper compression ratios, the pellets can not have an ideal form. ABC Machinery produces the die with different compression ratios according to the raw materials types guaranteeing the pellets quality.

ABC Machinery has single pellet mill die for sale, if you want to buy high quality of pellet mill die, you can contact us, and we won’t let you down!