Pelletizer Mill Turns Waste into Pellets Energy Sources

What is pelletizer mill?

General features of the pelletizer mill

Pelletizer mill is a mechanical equipment turning agricultural and forestry waste into density and flammable pellets through high heat and extrusion, so that we can make full use of it. And the pelletizer mill can be called pelletizer machine or pellet machine as well.According to its features, pellet machine is definitely a green equipment. Various of biomass materials can be processed by the equipment into pellets without anything added, like, wood chips, sawdust, rice husk, straw, corncob, grass, waste papers etc.. For the finished pellets, the density can be 1.1*10³kg/ m³, and the moisture content is controlled in a range of 10%-18%, thus, the pellets can be used as an energy fuel to become a solution to energy crisis.

Two types of pelletizer mill

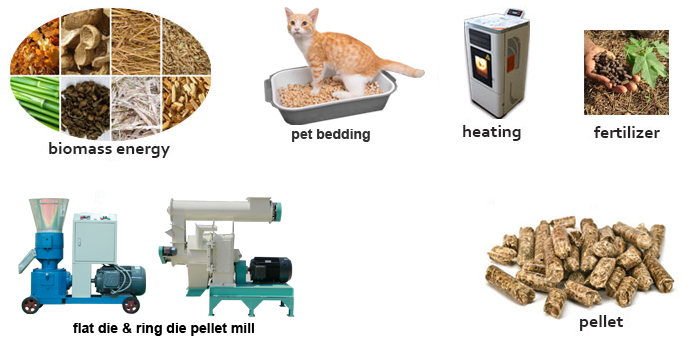

Mainly, the pelletizer mill consists of two parts, transmission part (motor, gear box and universal joint) and pelleting part (large shaft and pelletizing chamber). Because of the different working principle in the pelleting part, the pelletizer machine is divided into two types, flat die pellet mill and ring die pellet mill.

flat die pellet mill and ring die pellet mill

- Based on flat die structure design, the flat die pelletizer mill is designed with double-stage driving of belt and worm gear, rotating stably with low noise, feeding by the gravity to avoid blocking. The speed of the main axis is around 60 rpm, while the speed of the roller is 2.5 m/s, which can get rid of the gas of the material and increase the density of the production. And according to the turning pattern of the die and the press roller, it is divided into two types, the die-turned type and roller-turned type. Each type has been equipped with four kinds of powers, electric drive, diesel engine drive, gasoline engine drive and PTO drive.

- The ring die pelletizer mill is called because the shape of the die is like a ‘ring’. This ring die pelletizer machine is mainly composed of feeder, modulator, pelleting machine, lubrication system etc. The operation procedure requires the degree of the material mixed with powder should be not over 15 %. The material enters into the feeding auger through the stock bin. By adjusting the step-less speed regulating motor to change the speed, the material can flow moderately. Then the tempering begins through the paddle agitator mixing with the steam. After the tempering, the temperature of the material can be 64℃ to 84℃, and the humidity can be 14% to 16%. At last, the material enters into the pressing box to be pelletized through the chute.

Pelletizer Mill Price

The price of the flat die pelletizer mill is in a range of 20 thousand Yuan to 55 thousand Yuan for its output in 200-800kg per hour. While the price of the ring die pellet machine is in range of 70 thousand Yuan to 120 thousand Yuan with the feature of high output (500 kilograms to 3000kilograms per hour).Applications of pelletizer machine

Raw material decides application of pelletizer machine.For the materials like wood chips, corncob, peanut shells, cotton seed hull and other forestry and agro waste, the pellets can be used as fuel for home heating, industry stove and electricity factory etc.. Also, the agricultural waste like grass, rice husk, corn straw, bean shells can be turned into feed pellet for the farm, feed factory, fodder factory, tree farm etc.. Additionally, for the high absorption of the pellets, the pelleting equipment can be used for making animal bedding.

Commonly, the flat die pelletizer machine is used for home use and small scale pellet mill plant, while the ring die pellet mill is always used in feed factory, electricity factory and large scale pellet production line etc. for its high output.