Ring Die Pellet Mill or Flat Die Pellet Mill

Biomass densification technology drives the development of biomass pellet mill, and the technician developed two types of pellet mill, ring die pellet mill and flat die pellet mill. These two types of machines make people confused and they don’t know which machine to choose, ring die pellet mill or flat die pellet mill and which of them is better. The following gives the detailed introduction to ring die pellet mill and flat die pellet mill from the aspects of working principle, scale, price, and maintenance, etc.

1. Working principle.

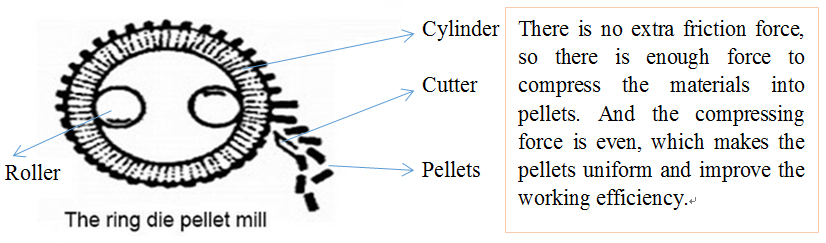

The working principle of ring die pellet mill is that, there are 2 to 4 rollers and driven roller with many grooves in the pellet mill. After the materials go into the ring die pellet mill chamber, the rollers in the cylinder with many holes will press the materials into the holes, and they will come out from the out of cylinder as the shape of pellet. There is a cutter outside the cylinder that will cut the pellet at a specified length.

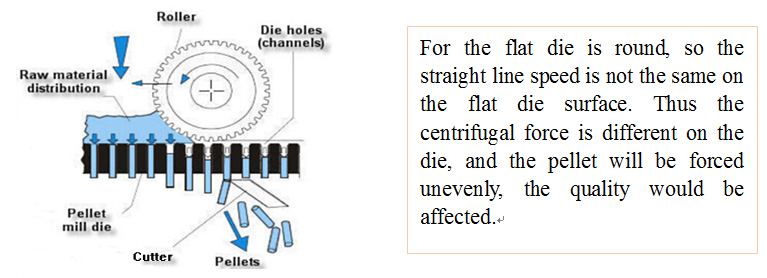

The working principle of flat die pellet mill is that, the materials fall on the flat die surface with many holes, and the roller will begin to press them on the surface of flat die into die holes. Then the materials will come out from the bottom of flat die in a form of cylinders. The cutter cuts the cylinders into specified length getting the end products.

2. Scale

The average output of ring die pellet mill is 1000-1200 tons, and the highest

output is up to 1800 tons. That greatly helps producers to increase the yield, and bring more benefits to them. So compared with flat die pellet mill, ring die pellet mill is suitable for large-scale production.

Flat die pellet mill is also called small pellet mill, which is portable and could move from one place to another. Flat die pellet mill brings benefits to the producers who want to change place. The small scale decides that the output of flat die pellet mill is lower than ring die pellet mill.

3. Price

output is up to 1800 tons. That greatly helps producers to increase the yield, and bring more benefits to them. So compared with flat die pellet mill, ring die pellet mill is suitable for large-scale production.

Flat die pellet mill is also called small pellet mill, which is portable and could move from one place to another. Flat die pellet mill brings benefits to the producers who want to change place. The small scale decides that the output of flat die pellet mill is lower than ring die pellet mill.

According to the above introductions, we can know that the price of ring die pellet mill is expensive than that of flat die pellet mill.

4. Maintenance

Due to the small volume of flat die pellet mill, it is easy to maintain the parts of flat die pellet mill by one person. While for the ring die pellet mill, it maybe need 2-3 persons because the rollers and dies are heavy to maintain or change.

5. Final products

Because the ring die pellet mill throws the pellets with the centrifugal force, and the pellets from flat die pellet mill fall down naturally, so the pellet broken rate of ring die pellet mill is higher than that of flat die pellet mill.

Both of ring die pellet mill and flat die pellet mill have their advantages, so you can choose one of them according to your requirement, and use them to bring you convenience and benefits.

Both of ring die pellet mill and flat die pellet mill have their advantages, so you can choose one of them according to your requirement, and use them to bring you convenience and benefits.