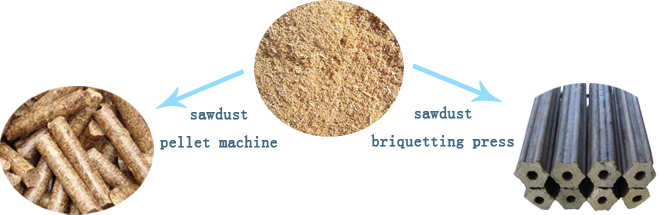

Sawdust Pellet Machine & Sawdust Briquetting Press

Sawdust pellets and sawdust briquettes have different shapes, different processing machines and different processing steps, but the same raw material---sawdust. Sawdust has rich lignin, so during the pellet & briquette making process, the rich lignin content can help them to shape perfectly.Usually speaking, the sawdust pellet machine and briquetting press are used in the production line.

Processing Steps

The first several processing steps of sawdust pellets and briquettes are similar, they are crushing and drying.

Crushing:

Generally, the sawdust from the furniture don’t have to be crushed, but they should be screened for there are impurities like metal, stones and other hard materials in the sawdust which may damage the pellet/briquette machine.

If the sawdust is from the chips or large , it should be crushed into the sawdust. So that needs the crusher or hammer mill. Too large or too small size of raw materials can not shape the pellet or briquettes well. The proper size of sawdust can go through the die hole and form different sizes of products.

Drying:

This step is to dry up the raw materials with about 50-55% of moisture content to 10-15% which is suitable for the pellet mill to form pellets while 12-20% for the briquette machine to form briquettes. During this step, the required machine is dryer/drying machine.

Sometimes, if the materials are too dry, you should add some water into the materials to make a proper moisture.

Ring Die Sawdust Pellet Machine

Sawdust Briquetting Press

Pelletizing in pellet making process:

Pelletizing is the main step in the whole process, it can turn the powder raw materials into rods with different length like 6mm, 8mm, 10mm. During the processing, you must control well the temperature and pressure, because those two factors are the key points to make pellets and decide the quality of end products. The lignin under 120-130℃ melts and it will have stickiness and bind the powder together. Finally the pellet mill will press the raw materials into pellets with high pressure.

Briquetting in briquette making process:

Briquetting is also the main step to make sawdust briquettes. The required machine is sawdust briquetting press. This machine can make the cylindrical briquettes and other shapes. The regular shape makes the briquettes easy to store and transport.

The next steps are cooling and packing, if the sawdust pellets or briquettes are used directly, you don’t need to pack them.

Cooling:

Cooling is an important step. If the products don’t experience this step, they can not shape perfectly, for the end products from the sawdust pellet mill or briquetting press are hot and easy to be out of shape. Cooling is to lower the temperature of sawdust pellets and briquettes making them to be hard. This step uses the cooling machine.

Normally, the sawdust briquettes don’t need the cooling machine, they are put on the shelf waiting to cool naturally.

Packing:

This is the last step in the whole production line. The packager packs the pellets and briquettes into bags for sale or other usages. If the products are produced in the small scale production line for private use, packing is not necessary.

Features of Sawdust Pellet Machine & Briquetting Press:

1. Both of them have different types of machine which can be used in large or small production line.2. The end products--sawdust pellets and sawdust briquettes have higher rate of complete shapes.

3. Most importantly, the combustion ratio of sawdust pellets and briquettes are higher.