Trusted Biomass Pelletizing Plant with Complete Solution

Biomass Pelletizing Plant Profile

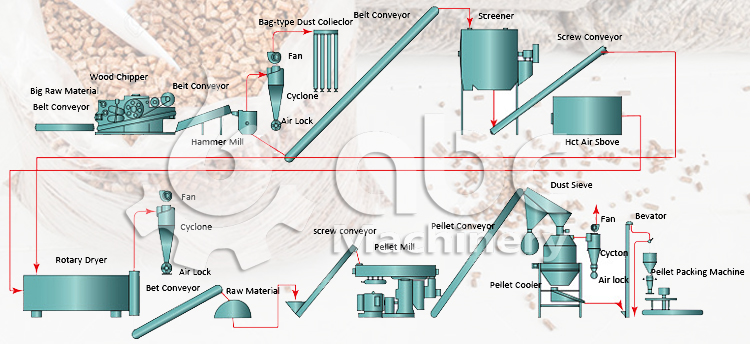

Biomass pelletizing plant adopts a series of pellet making equipment to produce pellets continuously with high efficiency and high pellet production. A great variety of biomass raw materials can be processed through the biomass pelletizing line, such as, woods, wood chips, shavings, sawdust, rice husk, peanut shell, pineapple shell, coconut shell, bagasse, corn stalk, straw, grasses, coffee shell, branches, twigs, corn rob, bamboo shavings etc. The finished pellet can be used for home heating and cooking, enterprises and public heating, BBQ, industrial boiler, power generation, household fireplace etc, therefore, biomass pelletizing plant is widely used for home use, industrial use and commercial use, even for investing use.

Key Equipment for Biomass Pelletizing Plant

In the biomass pelletizing line, the relative equipment can be added or reduced according to the raw material types, production requirement and other situations about the workshop, but the key equipment, pelletizing mill, can not be reduced, what can be changed is the type of pellet mill.Small Biomass Pelletizing Plant

- Small pellet plant can be called flat die pellet plant due to the flat die pelletizing mill as the key equipment, and the production of small pellet plant is decided by the flat die pelletizing mill, so, the production of small pellet plant ranges from 40kg/h to 500kg/h. Thus, small pellet plant is more suitable for home use, crop farm use, and if you are a new beginner, flat die pellet plant is suggested for you fro its easy operation and low cost.

Large Biomass Pelletizing Plant

- Large pellet plant adopts ring die pelletizing mill as the key equipment, which is called ring die pelletizing plant as well with the production ranging from 500kg/h to 2.5t/h. Ring die pellet plant is the optimal machine type for the people which want to produce biomass pellet for industrial use or commercial use for its large and continuous production.

Mobile Biomass Pelletizing Plant

- Mobile pellet plant adopts flat die pellet mill as the key equipment just like flat die pellet plant. Differently, the relative equipment like hammer mill, cooling conveyor, electric cabinet, vibrating screen etc are fully equipped, but with more compact structure and smaller size.

Why Do You Choose Biomass Pelletizing Plant?

- Wide raw material. all the biomass raw materials found in our daily life can be made into pellet like woods, wood chips, shavings, sawdust, rice husk, peanut shell, pineapple shell, coconut shell, bagasse, corn stalk, corn rob, branches, twigs, straw, grasses, coffee shell, bamboo shavings etc.

- Wide applications. Biomass pelletizing line can be widely used for home heating and cooking, crop farm residue treatment, industrial boiler, electricity generation etc.

- Biomass pelletizing plant can be customized for you according to your raw material, requirement and your local situation.

- Biomass pelletizing line, adopting the series of equipment to compose the pellet production line, saves the time cost of pellet production and help produce better quality pellet.

Moreover, the different types of biomass pelletizing plants have their own advantages.

- Small pellet plant, designed and developed with simple structure and low cost, covering a small area, is easy to install, operate and maintain, suitable for home use and new investors.

- Large pelletizing plant equipped with ring die pelletizing mill which is with better wear resistance, can produce pellet continuously, meeting the demand of industrial field and the pellet production factory.

- Just like flat die pellet plant, mobile pellet plant has the same advantages. But more conveniently, mobile pellet plant can be removed to any place that the users want for its more compact structure and smaller size.

Do have interest in one of our biomass pelletizing plant? Please contact us for more information.