Wood Pellet Mills on Hot Sale with – ABC Machinery

Wood pellet mill is one of the popular pellet mills at present market for its processing materials are rich and the price is low, many manufacturers choose to produce wood pellet mill for fuels. Wood pellet mill has many types, totally speaking, wood pellet mill is divided into small wood pellet mill and large wood pellet mill. They can almost process all kind of wood: hard wood like oak, birch, pine, poplar, etc and soft wood like beech, fir and so on.

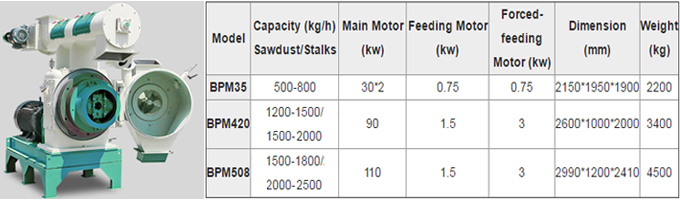

Large wood pellet mill is also named ring die wood pellet mill. Due to its large body and high capacity, large wood pellet mill is usually used in the large pellet mill production line. The main parts of large wood pellet mill are ring die and roller. Their position is different from the flat die and roller in small pellet mill. Ring die is a cylinder while the roller is in the flat die and the roller moves around the inner wall of the ring die. The working principle of wood pellet mill is similar to the small wood pellet mill. Both of them process the wood into wood pellets under high temperature and high pressure.

As for the raw materials , if they are wood logs, you need to handle them by using wood splitter, wood chipper, hammer mill, etc to make the wood logs more finer that is suitable for the wood pellet mill processing size. If the raw materials are wood chips, you have to use hammer mill to grind them into tiny pieces. While if the raw materials are wood sawdust, they can be processed directly. Besides, the moisture of raw materials should be proper. For too wet materials may cause the pellet mill to be blocked while too dry materials may cause the pellets not to be shaped well. So before processing the raw materials, you should control each factor related to the raw materials that you can get the best wood pellets.

After finishing the pellet making, you should handle the pellets according to the situation. If the wood pellet are used by yourself, you won’t need to use cooling machine to cool the pellets and to use packing machine to pack the wood pellets. Otherwise, it is necessary to cool and pack pellets. GEMCO wood pellet mills are for sale, if you have any need for wood pellet mill, contact us and we will give you the best service.