Best Charcoal Briquette Extruder Machine 2019

Making Charcoal Briquette for Daily Use

In order to obtain better combustion effect, the raw material for making charcoal fuel or charcoal powder are usually made into fuel which is shaped with cylinder with uniform diameter and length, high density. The final product is called charcoal briquette, which can be produced into different diameter from 12mm to 70 mm. The smaller one is usually used for home heating and cooking, bbq etc, while the larger one is usually used for public heating, enterprises heating, power generation plant etc.

Generally, the equipment used for making the charcoal briquette is named briquette extruder machine, and we always name the machine according to the final product. So, this machine is called charcoal briquette extruder machine, it has different types due to different working principle. Our featured charcoal briquette making machine is screw type and its charcoal briquette plant.

Charcoal Briquette Making Machine Line in Serbia>>

Charcoal Briquette Extruder Machine Introduction

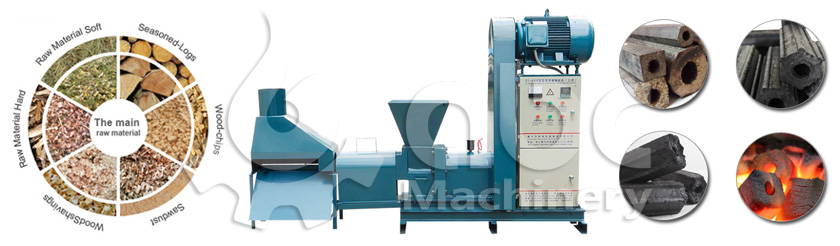

About Raw Material

Generally, the raw material is charcoal powder. But with our charcoal briquette extruding machine, the agro and forestry residues can be used as well. As long as the raw material size is less than 3mm and the moisture content is within 12%-14%, it can be used for making charcoal briquettes.

About Working Principle

When the raw material is put into the charcoal briquette extruder machine, the rotating screw will push them into the forming sleeve. Due to the pressure and friction inside the chamber, the raw material and water combines together better, then formed into settled shape through the forming sleeve, meanwhile, the ingredient of the raw materials comes much compact. Then the charcoal briquette is formed.Customized Charcoal Briquette Extruder Machine Plant for You

As we talk about the raw material requirement above, only the raw materials meets the requirement can be used for making charcoal briquettes. However, when collecting, not every raw material is in the size and moisture content, thus you need to equip the crusher and drying machine to realize. A series equipment like this is called charcoal briquette extruder plant. There are some other kind of machine equipped for better production, like cooling machine for fast decreasing the temperature of the finished briquette due to the high temperature in the charcoal briquette extruder machine; packing machine for rapid briquette packing.

As different places and regions have different living conditions and different customizers have different requirements, we have ability to customize the equipment for the customers from different place. We possess our own R&D team, with 20 professional technicians, seeking to researching the charcoal briquette extruder equipment, to give customers the best user experiences. We have more than 15-year experiences in building charcoal briquette extruder plant, exporting to over 50 countries, getting high praise from the customers around the world.

If you have any ideas about the charcoal briquette extruder machine, please contact us for more information.