How to Control the Production Cost of Fuel Briquetting Machine

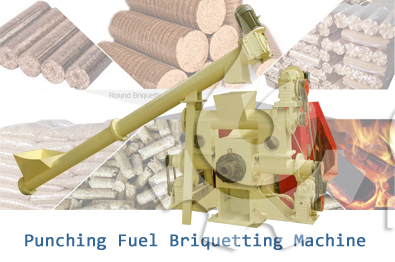

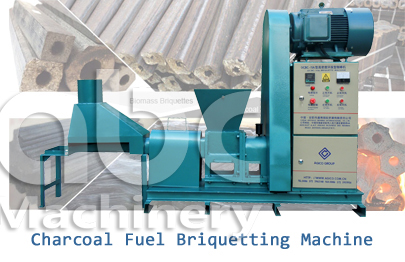

Fuel briquetting machine is one type equipment for producing fuel briquettes. As far as the present equipment types, it is divided into two big categories. One is the fuel briquette making machine used for making carbon rods, which generally means the multi-class smokeless carbon rod carbonized from hollow briquettes; while the other one is the wood briquettes, the cylindrical or square solid rod that pressed by the high temperature and pressure of briquetting machine. This article mainly shows that how to control the production cost of fuel briquetting machine.Raw Material Cost Control

Main raw materials used for fuel briquetting machine are sawdust and wood residues. If there are abundant woods, the raw material cost can be controlled within ¥150/t. Also you can buy biomass materials for making briquettes from the surrounding places. If the place is too far away, the transportation cost will be increased. Therefore, production base had better be build in the place near the raw materials.Carbonization Control

If there is too much ashes caused by avoiding excessive carbonization when using the carbonization stove, the carbonization period should be controlled well.

Fuel Briquetting Machine Production Details

Fuel briquetting machine is widely used for producing mechanical carbon briquettes. According to the raw materials differences, the carbon content, combustion value, calorific value are also different. The relationship between the calorific value of the charcoal produced by the fuel briquetting machine and the carbonization temperature is as follows:The calorific value of wood briquette is related to the carbonization temperature and heat preservation time directly. Under the condition of the same carbonization temperature and heat preservation time, the calorific value of the raw materials change. Generally, with higher carbonization temperature and longer heat preservation time, the carbon content and calorific value of the raw material will be higher. When the carbonization temperature is lower than 450℃, the calorific value of wood and other wood briquette made of material residues is generally is 6500~7000kcal / kg, the calorific value of briquettes made of straws and rice husk is generally is 6000kcal / kg. When the carbonization temperature is over 600℃, the caloric value can raise to 500~1000 kcal.

We are the professional briquetting machine manufacturer and supplier, providing you with the professional briquetting and carbonizing equipments, like wood fuel briquetting machines with various type and models, wood crushing machine, drying machine, carbonizing stove etc.