Analysis on Feasibility of Charcoal Briquetting Equipment

As our domestic economy develops fast, the demand for charcoal increases continuously. In order to solve the contradiction between supply and demand, our country is planning to support a large number of key new energy enterprises step by step in investment projects and tax policies, to build industrial system which is with scale, utilization of renewable resources or three wastes.

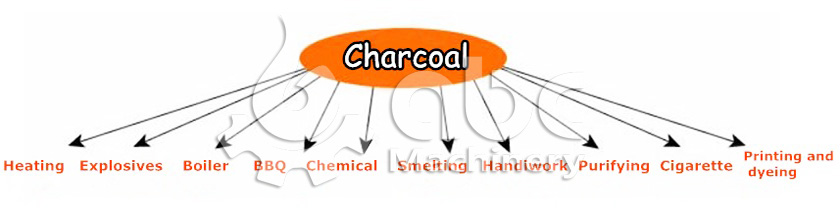

Charcoal Application

Charcoal is widely used in the field of food, medicine making, chemical, metallurgy, national defense, agriculture, environment protection and other industries, being the quality fuel for BBQ, hotpot, home heating etc. It is reported by the relative department that the number of charcoal needed for industrial silicon reduction reaches over 7 million tons; the charcoal needed for hotpot and BBQ is about 3 million tons; the charcoal number needed for heating in a part of regions is .5 million tons; the charcoal for water purifying reach to 0.5 million tons; charcoal used for exportation is 1 million tons. As thousands of years went, the charcoal is mainly produced by new forest cutting as the main raw material, while the new forest growing period is 10-15years, with 8 tons of new forest can be produced into 1 ton of charcoal, which destroys the forest badly. With carrying our policy of “returning farmland to forests, closing mountains for forest cultivation”, the contradiction between supply and demand has been increasingly prominent.

Turn Agro Residues into Charcoal Briquettes

How to protect the forest without destroying it as the cost, to provide quality charcoal around the market has been the dream of the scientific researchers for many years.

The charcoal briquetting equipment, designed and manufactured by the scientific researchers from our company, produces mechanism charcoal by using the agro residues as the material is featured of high quality, without wasting the forestry resources, meeting the national industry polices.

The charcoal briquetting equipment, designed and manufactured by the scientific researchers from our company, produces mechanism charcoal by using the agro residues as the material is featured of high quality, without wasting the forestry resources, meeting the national industry polices. Every one ton of charcoal costs 900 Yuan only, while the market price for one ton of charcoal is more than 2.5 thousand Yuan, which can be called very generous, giving good new to the small and middle enterprises who is ready to build charcoal briquetting equipment.

Advantages of charcoal briquetting equipment

The country greatly encourages the enterprises who use residues as materials to produce the mechanism charcoal, giving support in tax policies, getting great support from local government. What’s more, our General Administration of Customs and other departments have prohibited the import of briquette charcoal with size of over 4 mm diameter and 10mm long, while giving the mechanism charcoal briquettes the green permission. All this is to develop the road of green mechanism charcoal briquette production, opening up the overseas market of mechanism charcoal briquettes.

-

Environmental Protection Advantages

Green mechanism charcoal briquette is not at the cost of destroying forestry resources, easy to get the great support from local government, with successful plant approval process.

Green mechanism charcoal briquette is produced by using more than 70 categories and 300 kinds of materials as materials like agro straws, sawdust, shavings, rice husk, branches, bamboo sawdust, peanut shells, bagasse, distillers' solubles etc. Generally speaking, all kinds of biomass raw materials for combustion can be used for producing charcoal briquettes. Statistically, our country produce 700 thousand tons of agro residues straws, which has a short growing period inexhaustibly.

Compared with traditional charcoal briquette, green mechanism charcoal briquette has high combustion value, less ashes, no pollution, long combustion time, easy packing etc.

Green mechanism charcoal briquette sells 2500Yuan per ton, the production cost is about 900 Yuan per ton due to the adaptation of industrial production, which is as generous profits. However, traditional charcoal adopts artificial production which is with high cost, strong labors, low production efficiency, bad carbonization quality, burning with smoke produced, bad for the environment. The birth of mechanism charcoal briquette certainly will replace the traditional charcoal market due to its features of low cost, high quality. And the bamboo charcoal is especially shortage, with the price over ten thousand Yuan, meaning higher profit. All this shows that the cost is different according to the different raw material price.

Cost Analysis List of Charcoal Per Ton

|

Number |

Exemplary case |

Unit |

Qty |

Unit price (Yuan) |

Sum (Yuan) |

Note |

|

1 |

Dry raw material |

Ton |

2-2.5 |

200 |

500 |

Reference only |

|

2 |

Water |

Ton |

1 |

2 |

2 |

|

|

3 |

Electricity |

Ton |

210 |

1 |

210 |

|

|

4 |

Dryer fuel |

Ton |

0.5 |

100 |

50 |

|

|

5 |

Workshop rental fee |

Ton |

|

|

|

Self-control |

|

6 |

Equipment depreciation |

Ton |

50000 |

25 |

10 |

10 year depreciation |

|

7 |

Wage |

Ton |

2-3 persons |

|

150 |

|

|

8 |

Taxes |

Ton |

|

|

10 |

According to different regions |

|

9 |

Total cost |

Ton |

1 |

|

930 |

Final product per ton |

|

10 |

Charcoal selling price |

Ton |

1 |

|

1800 |

Ex-work average price |

|

11 |

Profit |

Ton |

1 |

|

870 |

|

(The cost analysis above changes according to the market price of every place)

Build your charcoal briquette factory now! Tencent Us!

The charcoal briquetting equipment, designed and manufactured by the scientific researchers from our company, produces mechanism charcoal by using the agro residues as the material is featured of high quality, without wasting the forestry resources, meeting the national industry polices. Every one ton of charcoal costs 900 Yuan only, while the market price for one ton of charcoal is more than 2.5 thousand Yuan, which can be called very generous, giving good new to the small and middle enterprises who is ready to build charcoal briquetting equipment.

The charcoal briquetting equipment, designed and manufactured by the scientific researchers from our company, produces mechanism charcoal by using the agro residues as the material is featured of high quality, without wasting the forestry resources, meeting the national industry polices. Every one ton of charcoal costs 900 Yuan only, while the market price for one ton of charcoal is more than 2.5 thousand Yuan, which can be called very generous, giving good new to the small and middle enterprises who is ready to build charcoal briquetting equipment.