How to Make Green Fuel with Briquette Making Process

Waste Treatment around the World

Everyday, a mass of waste is produced around the world, waste treatment has also been a world problem around the world. Recently, waste treatment becomes a hot topic around the world.

After waste recycled, waste treatment comes to the next step. With briquette making process, the waste can be easily produced into used green briquette fuel used for daily life.

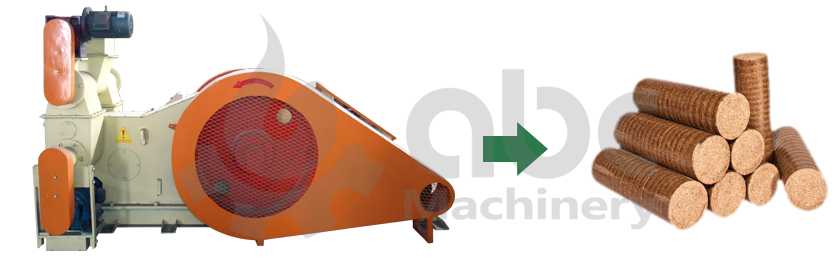

About Briquette Making Machine

A briquette making machine is used to process the raw materials into briquette machine, which is the moist important equipment in the briquette making process. It is generally divided into three type, respectively are punching briquette making machine, screw briquetting machine and double heads multi-functional mechanical briquetting machine.Punching briquette machine

Punching briquette machine is one of the biomass briquette machine, is able to produce cylindrical solid briquette with different sizes. Adopting the principle of mechanical stamping, punching type has large pressure on the materials, easy to form the high density briquette fuel.Screw briquetting machine

Screw type briquette machine is also called charcoal briquette machine. Adopting the screw principle, it use the propeller to push the materials into the forming sleeve. The final briquette is in the shape of charcoal and biomass briquettes with cylindrical or hollow centers.Briquette Making Process

In common, briquette making process consists the following process

- Raw materials collection

- Raw material process

- Briquetting process

- Cooling and packing process

All the briquette making process mentioned above is the general process, we can customize the most suitable briquette production line based on your requirement and actual condition. If you have any idea about briquette making process, please contact us for more information.