How to Operate and Maintain Industrial Briquette Machine

What is Industrial Briquette Machine?

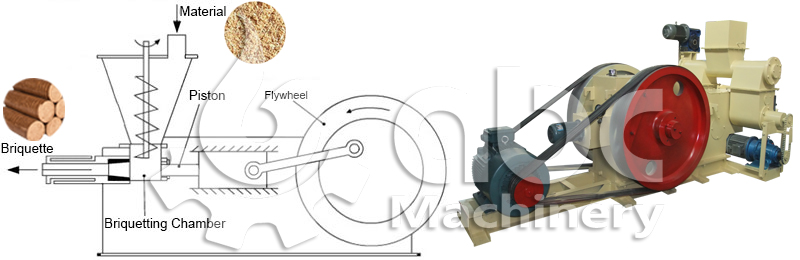

Briquette machine processes the agro and forestry residues like sawdust, straws into fuel briquettes. During the production, the raw materials containing lignin is formed into solid briquettes which has high combustion resistance through the high temperature and pressure inside of the briquette machine. This forming processing is based on scientific principle. There are lots of lignin and cellulose in the plants, and the lignin has not melting point but with softening point. When the temperature reaches to 120~160℃, the soluble matters of the lignin in the plants start to soften, which will be able to be formed easily in the temperature of 180℃, at this time, with a certain pressure on the raw materials, the lignin will adhere to the cellulose and cement with the adjacent particles. The briquetting technology uses this feature of the plants to form them into briquettes through heating and extruding. With briquette machine, not only the residues problem is solved, but also the high demand of the fuel market can be relieved well.How to Operate and Maintain Industrial Briquette Machine?

The industrial briquette machine manufactured by our company is featured with stable performance, large output. The normal operation can reach to or over the standard output. So, how to check the operation is normal or not?- Check the motor voltage run stable. After checking, the lubrication parts of important components are normal and safe.

- Tighten all the connecting screws, especially for the three jackscrews in the inner sleeve of heating cylinder, connect the cooling water pipe, also the machine should be connected to the power circuit.

- Before starting the machine, it need to run without loading for about 30 minutes. If the noise is not found during the running, the raw materials can be fed into the machine for production.

- When starting the briquette machine, the temperature of the industrial briquette machine should be adjusted in the required temperature, when reaching to the requirement, feeing the raw materials with the gradual feeding method, meanwhile carefully check all the produced briquettes are qualified.

Professionally Equipped Industrial Briquette Machine Plant

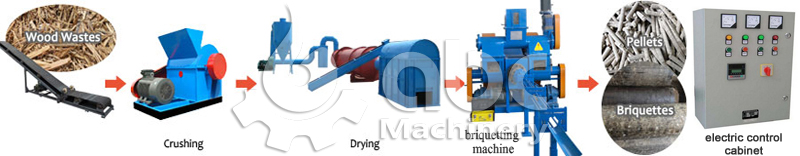

Industrial briquette machine is manufactured with large output, generally used with crushing machine, drying machine in the briquette production line. Take the wood chips briquette production for example, the complete production line includes crushing machine, drying machine, briquette machine (equipped with conveying device, feeding machine, depiler, main engine, controlling cabinet ) etc. The industrial briquette machine provided by our company adopts the screw preloading, piston stamping, second-class compression process, oil forced cooling, to make sure the mechanical lubrication, solving the high requirement from the common briquette machine for the sawdust moisture content and the shortage of quick component wearing. This equipment possesses with low electric consumption, high production efficiency, long lifetime, low maintenance rate etc.Click here to know about how to customize your own industrial briquette machine. We are always here for your coming.