How to start a pellet mill factory

Why do you need a pellet mill factory?

Sawdust pellets is one of the state encourages the development of clean and environmentally friendly renewable biomass energy, do your fireplace or boiler heating fuel are available, and used more widely in Europe and America region. Mainly made from sawdust and other agroforestry processing residues. After drying and high temperature compression molding.Because sawdust pellets are strong compressed, its burning efficiency is very high, and the moisture content is low (about 6% to 10%), there is almost no harmful gas is released. The combustion efficiency more than 95% (60% on average coal) are similar to those of high quality coal. The release of sulfur dioxide, ammonia compounds and dust is minimal.

The sawdust pellets can be used for specially designed fireplaces and boilers for heating. The size of sawdust particles is consistent (2cm to 3cm in length and 6mm to 8mm in diameter). The low amoisture and high density of sawdust particles means it can be burned automatically and cleanly in the heater. In addition, some existing boilers using solid and oil can also be converted to wood chips pellets. Wood chips pellets are usually made from wood processing waste, such as board heads and sawdust, without any chemical additives.

High income with pellet mill factory

Analysis on benefit of investing environmental biomass pellet mill factory1. Construction conditions:

The area of a workplace is about 30m^2 to 120m^2 that is divided into crushing workshop, granulation workshop, molding workshop, the amount of space to store the raw material or otherwise material reserve warehouse size. Reserves warehouse, the bigger the better, three-phase power supply, production workers, 1-3.

2. Profit analysis:

- Raw material cost: (whether tree branch, root, leaf, tree bark,or after pulverizing, it is collectively referred to as sawdust: the cost of its cost is 150-300 yuan/ton), i.e., 300X5 = 1500 yuan.

- Electricity cost: The equipment produces a per ton of biomass need comprehensive electricity is 80 kilowatts. (the large equipment needs only 50 yuan per ton of electricity, and Electricity price varies by 1 yuan/degree) 80X5 = 400yuan.

- Wage :100yuan per person per day. (the standard of living varies from 3000 yuan for one month.) 3 people X100 = 300/day.

- Workshop fee: 30/day.

- Equipment depreciation and other expenses 20/day.

- Production comprehensive cost:2250/day.

- Factory price per ton of sawdust pellet: 900.

- Profit per day:900/ton *5ton - 2250/day=2250/day.

- Profit per month: 2250/day *30days=67500.

- Profit per year:67500yuan *12=810000.

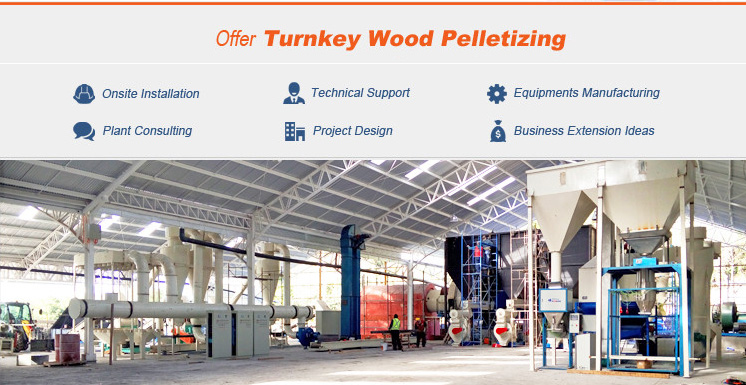

ABC Machinery the BEST professional manufacture biomass pellet mill, wood pellet mill and other wood pellets processing equipment. The price is low, the quality is excellent, the performance is stable, belongs to the eu CE certification enterprise. With 80 percent of the products made overseas, the company is deeply loved by our users.